Analog Vs. Digital Servos: Understanding The Differences For Optimal Control

In the realm of robotics and automation, servos play a crucial role in precise positioning and control. However, choosing the right type of servo for your specific application can be a daunting task, especially when it comes to selecting between analog and digital servos.

Unveiling the Enigma of Servos

Servos are electromechanical devices that convert electrical signals into precise angular or linear motion. They are typically used in applications where accurate positioning and control are essential, such as robotics, industrial automation, and medical equipment.

Demystifying Analog and Digital Servos

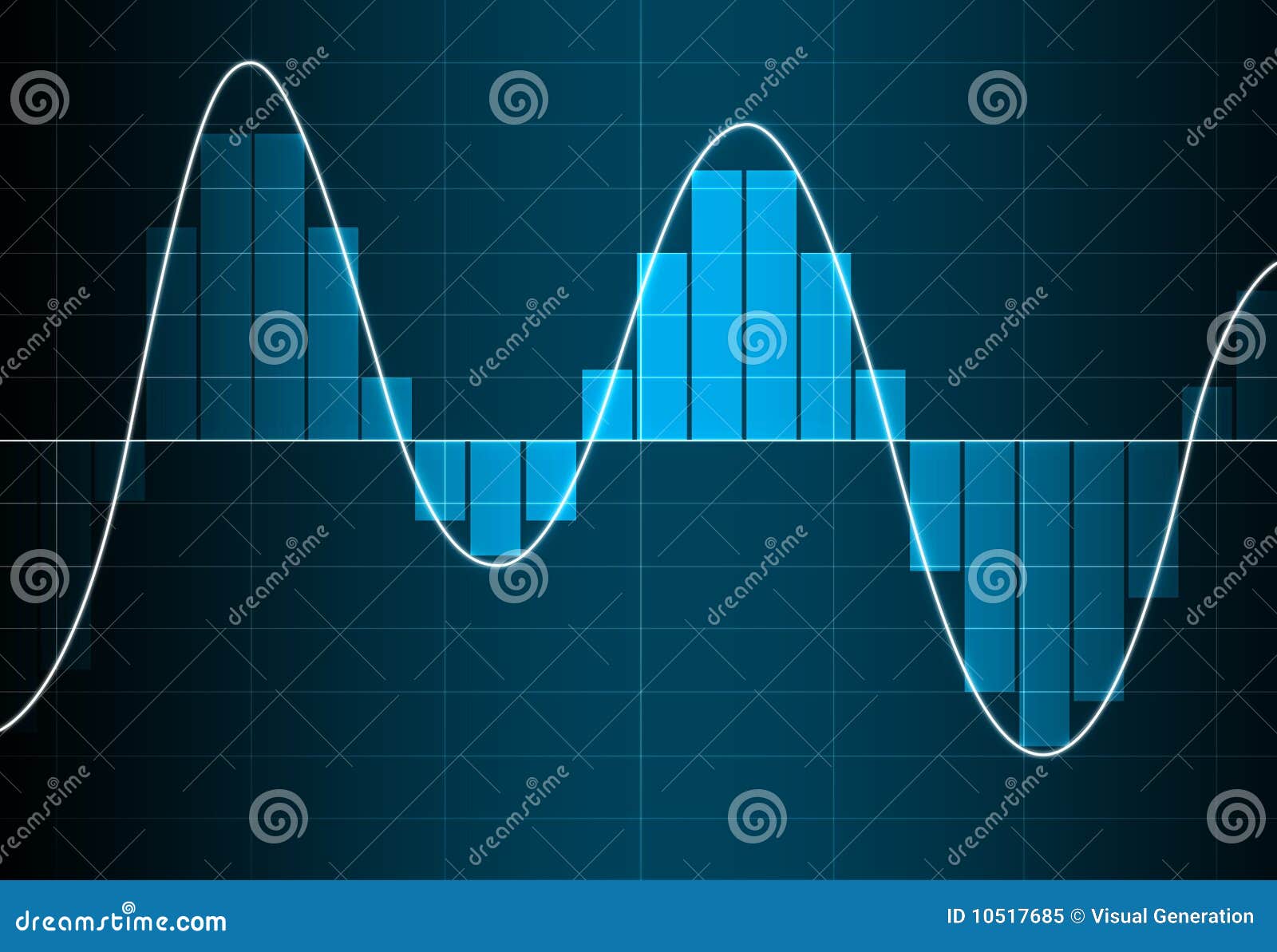

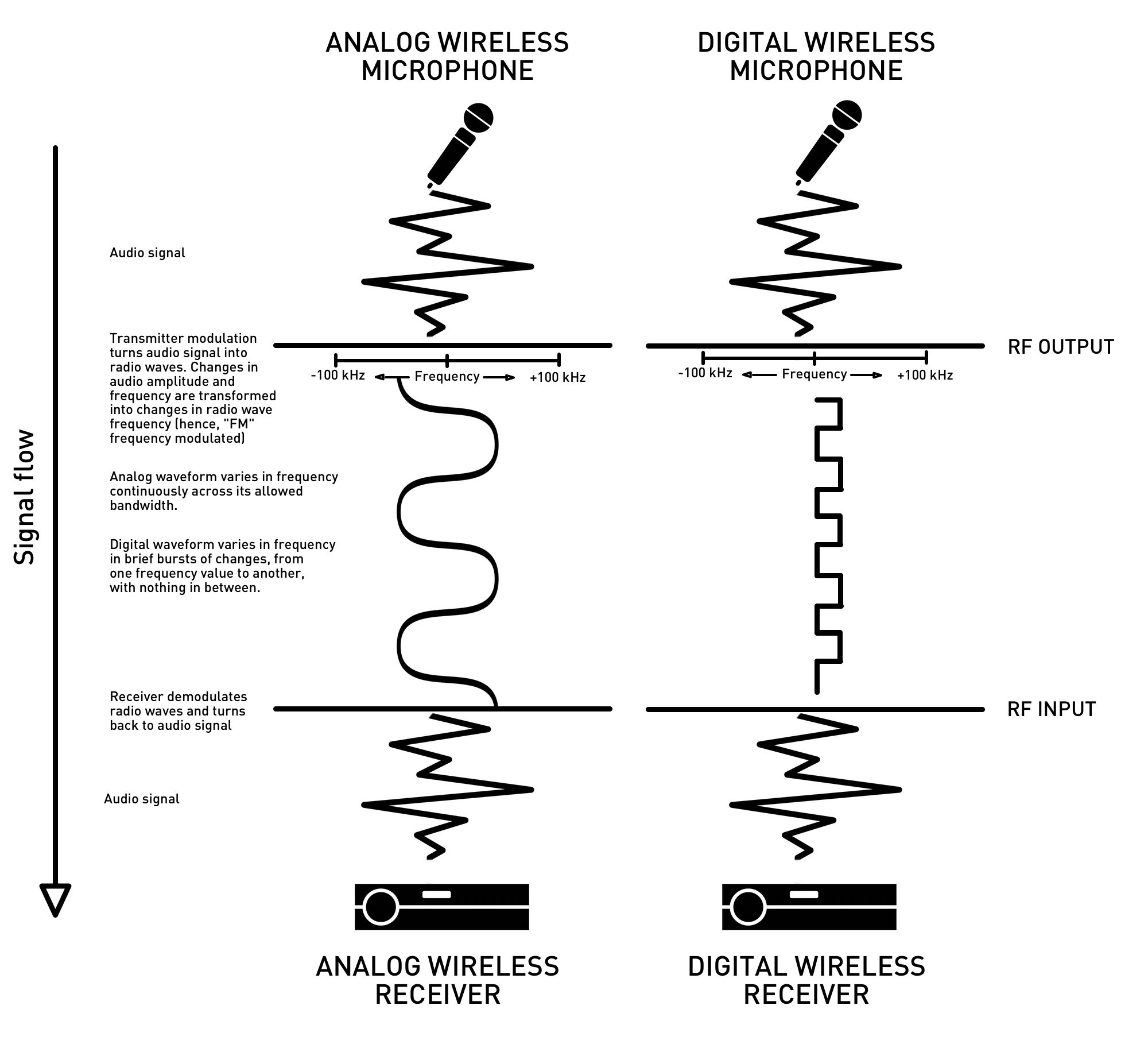

Analog servos utilize a continuous electrical signal to control their position, while digital servos rely on a digital pulse-width modulation (PWM) signal. This difference in signal processing gives rise to distinct characteristics and applications for each type of servo.

Analog vs. Digital Signals Research Wkst – Name – Source www.studocu.com

Analog servos offer smooth and precise movement, making them suitable for applications requiring fine control. They are commonly used in hobbyist robotics and educational projects. On the other hand, digital servos provide higher accuracy and reliability, making them ideal for industrial applications and high-performance robotics.

The Intriguing History of Servos

The concept of servos dates back to the 1930s, with the invention of the first analog servo by American engineer Harold Black. Digital servos emerged later, in the 1970s, with the advent of microcontrollers and digital electronics.

Analog vs. digital effects for recording guitar: Exploring the timeless – Source splice.com

Over the years, servos have undergone significant advancements, with the development of brushless motors, high-resolution encoders, and advanced control algorithms. This evolution has led to servos that are more efficient, accurate, and versatile.

The Enigmatic Secrets of Servos

Like any technology, servos have their share of hidden secrets. For instance, some high-end digital servos incorporate sophisticated algorithms that predict and compensate for errors, resulting in exceptional accuracy and response time.

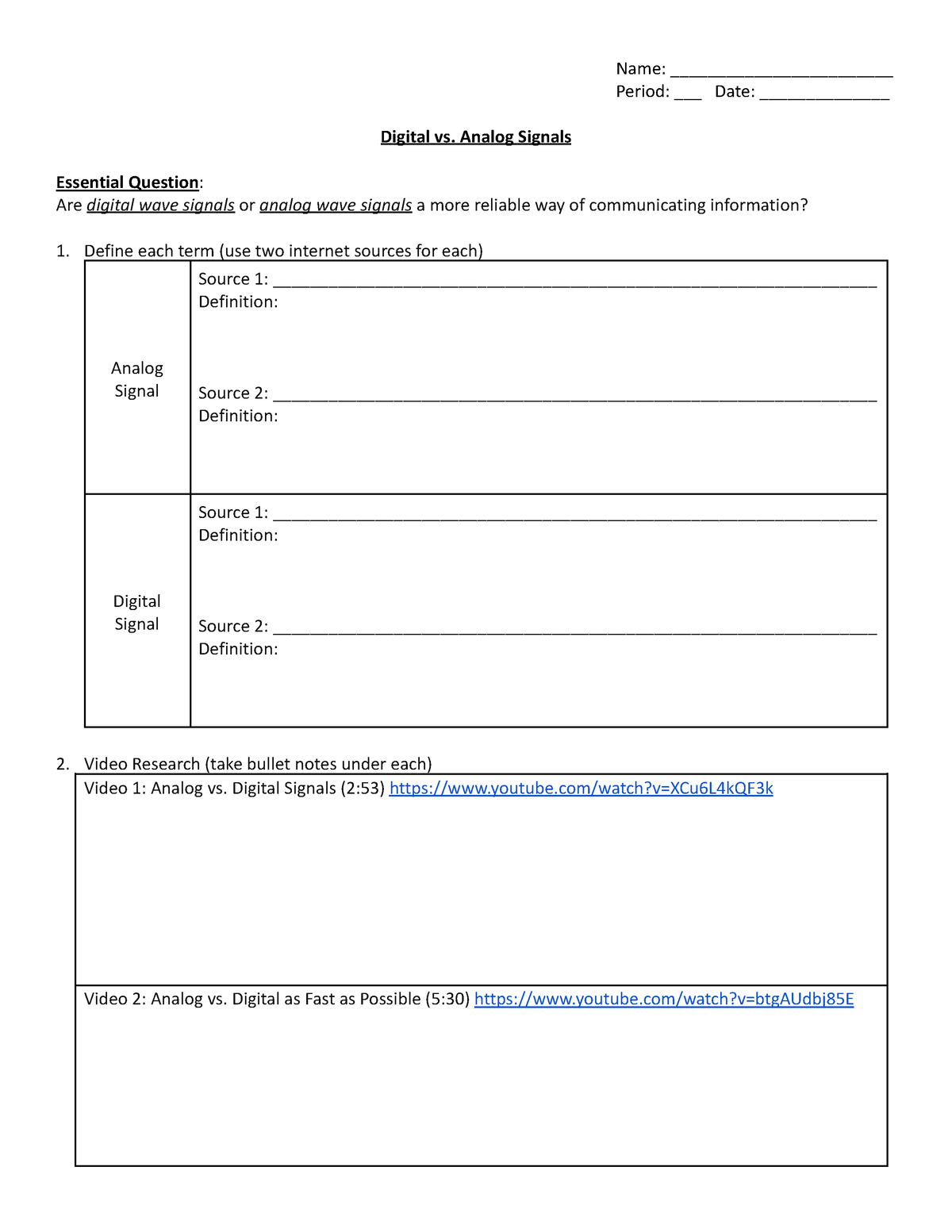

Analog and Digital Signals in Computer Networking | 5 Differences – Source digitalnoteshub.com

Moreover, some servos feature built-in sensors and feedback loops, allowing them to monitor their own performance and adjust accordingly. This self-monitoring capability contributes to increased reliability and precision.

The Wisdom of Choosing the Right Servo

Selecting the optimal servo for your application requires careful consideration of factors such as accuracy, speed, torque, and environmental conditions. Analog servos are suitable for applications where smooth movement and fine control are paramount.

Analog Cartoons, Illustrations & Vector Stock Images – 64479 Pictures – Source cartoondealer.com

In contrast, digital servos are the choice for applications demanding high precision, reliability, and response time. Understanding the differences between analog and digital servos will empower you to make informed decisions for your specific requirements.

Tips for Enhancing Servo Performance

To maximize the performance of your servos, consider employing these tips: Use high-quality power supplies to ensure stable voltage and current. Mount servos securely to minimize vibrations and ensure accurate positioning. Regularly calibrate servos to maintain optimal performance.

Analog vs Digital Media: Which is Better? | Klipsch – Source www.klipsch.co.uk

Avoid overloading servos, as this can lead to premature failure. Implement proper feedback mechanisms to enhance servo responsiveness and accuracy. By following these guidelines, you can ensure your servos operate reliably and efficiently.

Troubleshooting Servo Problems

If you encounter problems with your servos, start by checking for loose connections or damaged components. Test the servo power supply to ensure it delivers the correct voltage and current. Check servo settings and adjust them if necessary.

Understanding the difference between Analog and Digital Signals – Source crossroadenergy.com

Consider replacing the servo if it exhibits persistent errors or malfunctions. Consulting with experts or referring to manufacturer documentation can also provide valuable insights for troubleshooting.

Fun Facts About Servos

Did you know that some servos are capable of generating impressive torque? High-performance servos can produce torque values that far exceed their physical size. This makes them suitable for applications requiring precise movement and high force.

Analog vs. Digital Drum Sound Design (2024 Guide) – Blog | Splice – Source splice.com

Servos are also used in various non-robotic applications. They can be found in camera stabilizers, automotive systems, and even medical devices. Their versatility makes them essential components in a wide range of industries.

How to Maintain Servos

Proper maintenance is crucial for extending the lifespan and ensuring the optimal performance of your servos. Regularly clean and lubricate servos to minimize wear and tear. Store servos in a dry and protected environment to prevent corrosion.

Measurement Techniques Analog Vs Digital Yokogawa Industry Blog | My – Source www.myxxgirl.com

Inspect servos periodically for loose screws or damaged parts. Replace worn-out components as needed to maintain peak performance. By following these maintenance guidelines, you can ensure your servos operate reliably for years to come.

What if Servos Fail?

In the event of servo failure, it is important to identify the cause promptly to prevent further damage. Analyze the symptoms and refer to manufacturer documentation for troubleshooting steps. Consider replacing the servo if repairs are not feasible or cost-effective.

Watch Bands | Leather Watch Bands – A Comprehensive Guide– Strapcode – Source www.strapcode.com

Having a spare servo on hand can minimize downtime in critical applications. Proper maintenance and careful operation can significantly reduce the risk of servo failures.

Listicle of Servo Applications

Servos find applications in countless fields, including: Robotics: Servos are used to control joint movement and provide precise positioning in robots.

Analog Vs Digital Displays Linus Tech Tips – vrogue.co – Source www.vrogue.co

Industrial Automation: Servos are essential for accurate positioning and motion control in manufacturing and assembly processes. UAVs and Drones: Servos enable precise control of flight surfaces and camera gimbals in unmanned aerial vehicles.

Question and Answer

Q: What is the difference between analog and digital servos? A: Analog servos use a continuous electrical signal, while digital servos use a digital pulse-width modulation (PWM) signal.

Q: Which type of servo is better? A: The choice between analog and digital servos depends on the specific application requirements. Analog servos offer smooth movement, while digital servos provide higher accuracy and reliability.

Q: How do I maintain servos? A: Regularly clean and lubricate servos, inspect them for loose screws or damaged parts, and store them in a dry and protected environment.

Q: What if a servo fails? A: Analyze the symptoms and refer to manufacturer documentation. Consider replacing the servo if repairs are not feasible or cost-effective.

Conclusion of Analog Vs. Digital Servos: Understanding The Differences For Optimal Control

Understanding the differences between analog and digital servos is essential for selecting the optimal servo for your specific application. Consider the accuracy, speed, torque, and environmental requirements to make an informed decision.

Proper maintenance and troubleshooting techniques will ensure your servos operate reliably and efficiently. By leveraging the information provided in this article, you can harness the power of servos to achieve precise control and movement in your projects and applications.